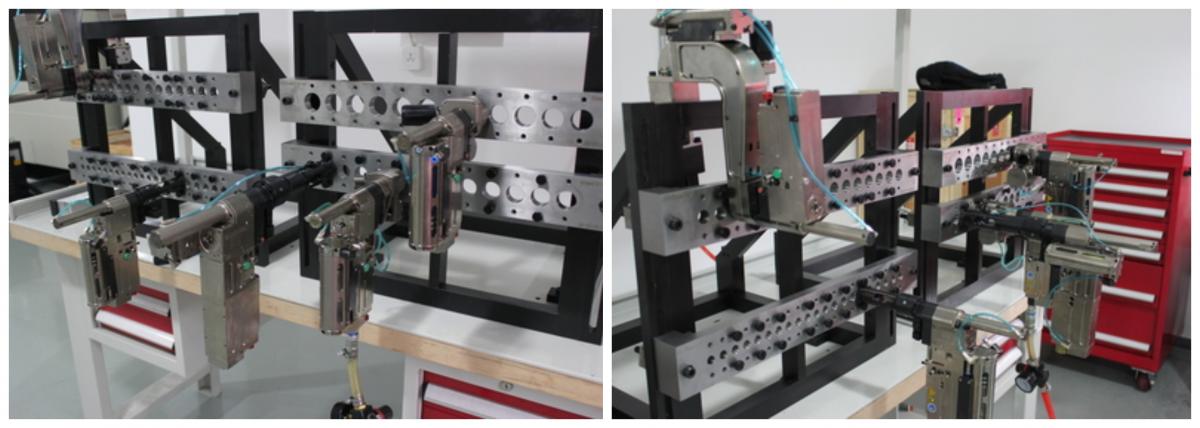

Tooling for Advanced Drilling Units

Mohawk's custom designed advanced tooling , aligned with a carefully selected "Power Tool" can provide great flexibilty and precision in the manufacturing process. To function as effectively as possible, all cutters must be carefully engineered to ensure that our customer receives a cutting tool that allows them achieve required hole size, alignment, roundness and surface finish.

Mohawk's custom designed advanced tooling , aligned with a carefully selected "Power Tool" can provide great flexibilty and precision in the manufacturing process. To function as effectively as possible, all cutters must be carefully engineered to ensure that our customer receives a cutting tool that allows them achieve required hole size, alignment, roundness and surface finish.

Mohawk's application specific approach to tool design helps assure that you receive the correct tooling for all applications.

As many aerospace components and assemblies are too large for conventional CNC tooling, there is a clear need for ADU's that are portable, easily fixtured, accurate and powerful-without sacrificing productivity.

Unique Features of Cutting Tool

- Thru the cutter lubrication

- Drill geometry with point designed specific to material

- Cutter run out from shank to point less than 0.010mm (0.00025")

- Advanced coatings available

- Select grade of carbide ensuring long tool life

- Chip breaker capability on point

Materials our products can be used on:

- Alu/Ti/CFRP

- Ti/CFRP/aL

- CFRP/CFRP

- Alu/CFRP/Alu

- Various configurations of all materials

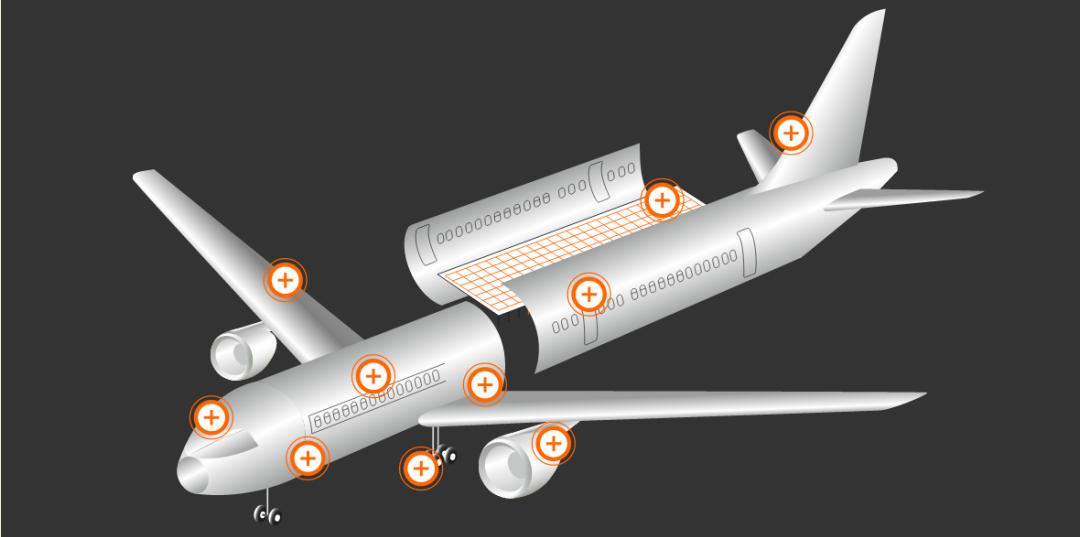

Examples of where ADU's and custom tooling can be effective.

Horizontal Stabilizer

Wing Assembly

Aerilon Flap

Mohawk R&D Facility

Our advanced Research and Development facility on site, helps develop the most up to date technological and geometric advancements in the industry to ensure all our customers requirements are met to the highest standards.